Turn Your Front Line Into Cost-Conscious Problem Solvers —Without Hiring a Single Engineer

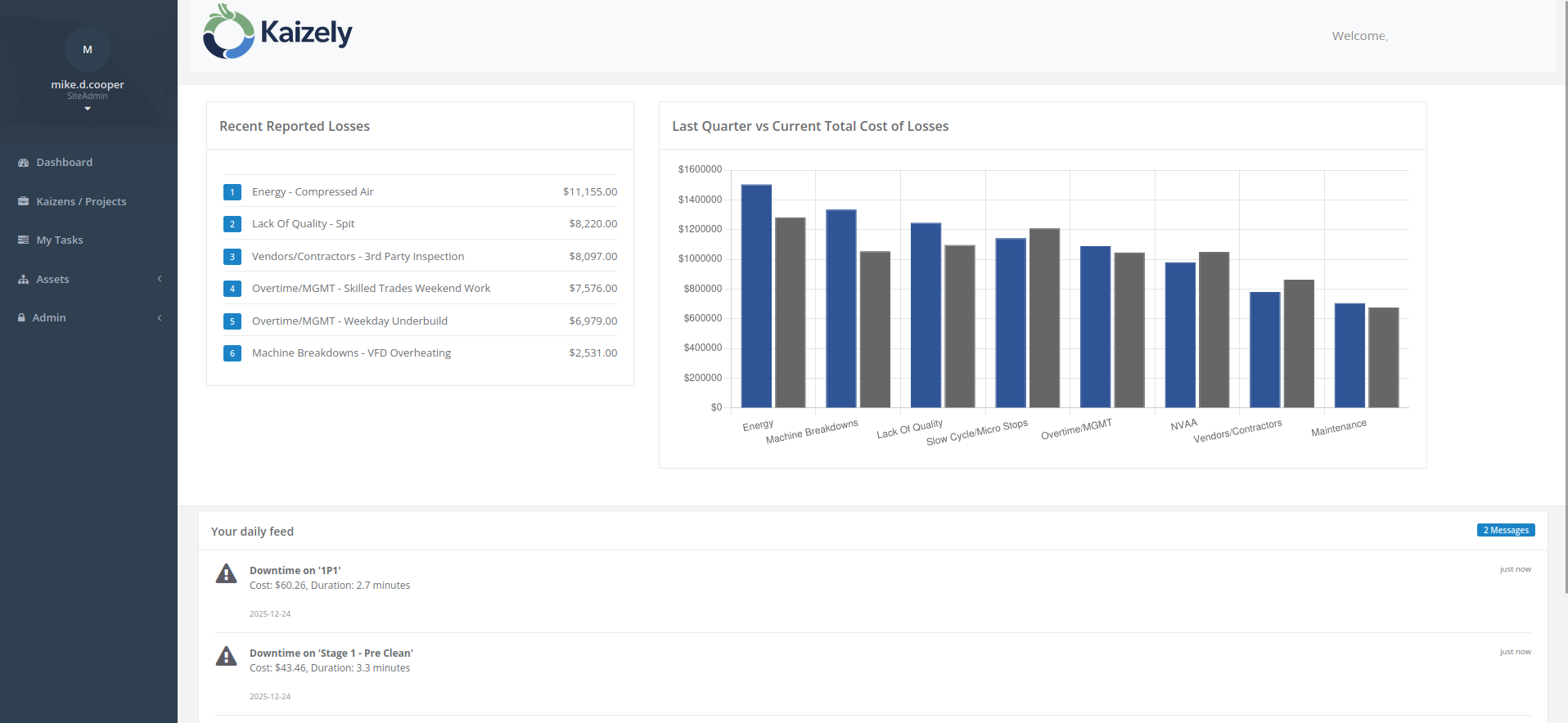

Kaizely makes Focused Improvement simple: Every downtime event, every defect, every loss automatically converts to dollars. Your team sees the impact instantly and learns to attack your biggest costs first. No spreadsheets. No guessing. Just clear priorities based on what actually hits your P&L.

Is This Your Daily Reality?

You're fighting fires—but are you fixing the problems that actually impact your P&L?

Production Manager

- "My team fixes the same 3 machines repeatedly, but I can't prove we're ignoring bigger problems"

- "I send people to RCA training, but they still don't know which failures to prioritize"

- "Finance keeps asking 'what's this downtime costing us?' and I'm stuck building spreadsheets for a week"

Maintenance Manager

- "I know Machine 7 has the most breakdowns, but is it actually our biggest cost driver?"

- "My techs are great at fixing things, but terrible at documenting root causes in a way leadership understands"

- "We track MTBF and MTTR religiously, but execs only care about dollars—I can't translate"

Plant Controller

- "Operations sends me maintenance logs and downtime reports, but I can't tie them to actual cost impact"

- "I'm supposed to find $2M in cost reductions this year, but I don't know which operational improvements deliver real ROI"

- "Every department has 'critical' projects—but which ones actually move the P&L?"

Kaizely solves this by making every loss speak the language everyone understands: dollars.

Now your floor workers, maintenance techs, and finance team are all looking at the same number—cost impact—and prioritizing the same problems. No more translation. No more guessing. Just clarity.

The Manufacturing Priority Problem

Your team is working hard on continuous improvement. But are you fixing the $5K problems while $500K problems go unnoticed?

Traditional CI Platforms

Collect data, track metrics, generate reports. But they leave you guessing: Which problems actually matter to the bottom line?

Kaizely's Approach

Converts every problem into dollars—automatically. Everyone from operators to executives speaks the same language: cost impact.

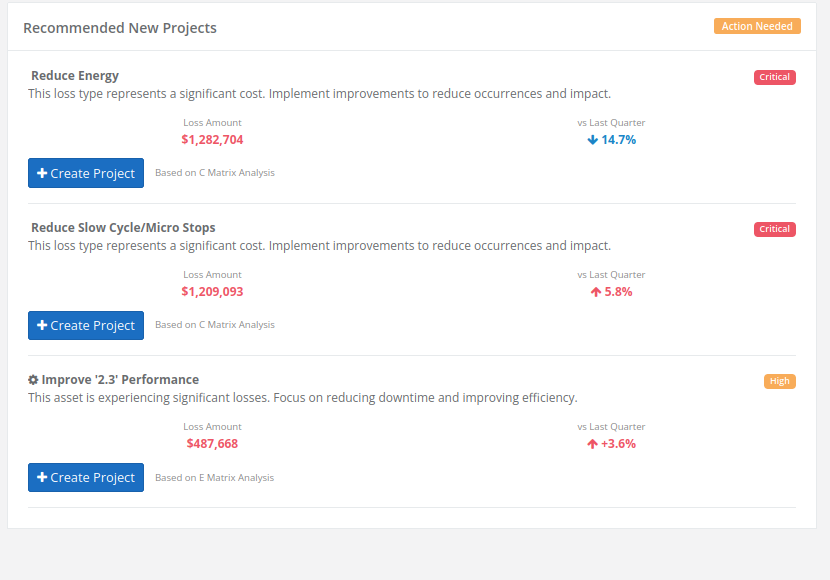

Smart Project Recommendations

Let AI analyze your loss data and recommend the next projects to launch—automatically.

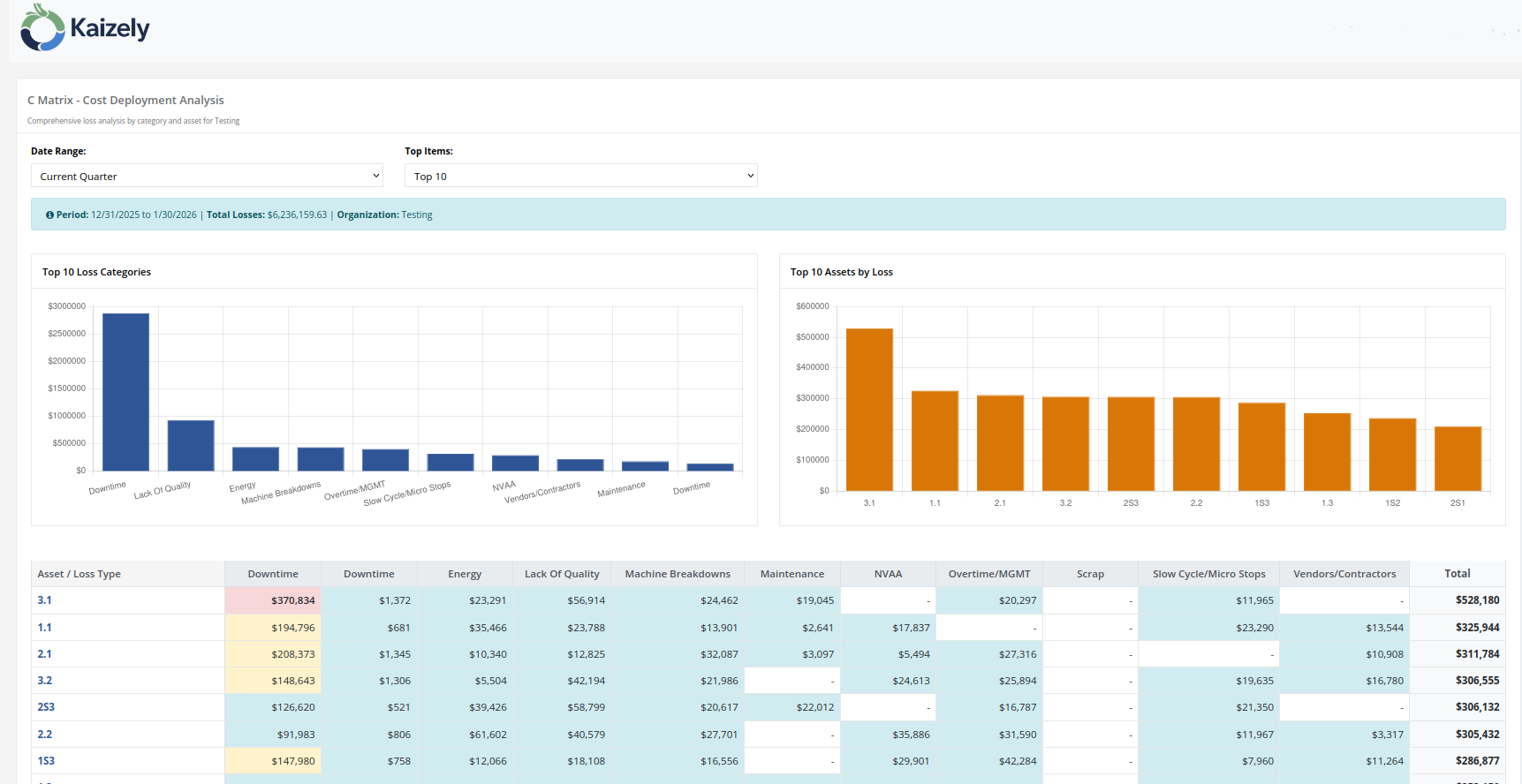

Top Loss Identification

Automatically identifies your highest-cost loss categories based on current quarter data. Attack your worst financial impacts first with data-driven confidence.

Emerging Loss Detection

Detects rapidly increasing losses before they become major problems. Catch trends early and prevent significant future costs with proactive intervention.

Asset Performance Insights

Identifies underperforming equipment requiring immediate attention. Focus improvement efforts on assets with the greatest impact on your bottom line.

One-Click Project Launch

Create new continuous improvement projects instantly with pre-populated data. Go from recommendation to action in seconds, not hours.

Founding Customer Program

Join the first 5 companies to transform their operations with Kaizely

What's Included:

- Unlimited users

- Unlimited integrations

- TPM & Kaizen tools

- Priority onboarding support

- Direct product roadmap input

- CSV import & public API access

- Standard support

- Success story / case study participation

- Testimonial for marketing materials

- Quarterly feedback sessions

- Reference calls with qualified prospects

After first year: Standard pricing ($499/month per facility) with 5% annual increase applies.

Limited to 5 companies - applications reviewed within 48 hours

From Firefighters to Problem Solvers: Develop Your Team While Cutting Costs

The best part? Kaizely doesn't just save money—it transforms how your people think.

What Happens When Every Worker Sees Cost Impact

Start asking: "Which quality defects cost the most?"

(instead of just counting rejects)

Prioritize: "Let's fix the $50K/month failure mode first"

(instead of the loudest squeaky wheel)

Focus: Improvement projects on the top 3 cost drivers

(instead of random kaizens with no ROI tracking)

Your team develops RCA skills on problems that actually matter . They see their impact in dollars saved. They build problem-solving muscle while driving real P&L improvement.

- Junior techs learn by tackling real $100K problems

- Everyone speaks the same language: dollars

- Skills compound as team solves bigger challenges

- Best practices spread naturally across shifts

Transform Workers Into Problem Solvers

Every feature builds workforce capability while cutting costs

Turn Every Worker Into a Cost Analyst

Automatic cost translation means even a brand-new operator understands impact. When they see "2-hour downtime = $4,800 lost," they get it. No MBA required. This is how you build a culture where everyone thinks like a business owner.

Teach RCA on Problems Worth Solving

Your team learns 5 Whys, PDCA, and root cause analysis on your actual biggest cost drivers—not random small issues. Guided workflows ensure they practice problem-solving on the $100K problems, not the $500 annoyances.

Match Skills to High-Value Problems

Track who's good at what, then deploy the right expertise to your worst costs. Junior tech gets the routine stuff; your best troubleshooter tackles the $200K downtime problem. Maximize impact while developing your bench.

From Data Chaos to Clear Priorities

Your MES, SCADA, and quality systems generate mountains of data. Kaizely automatically converts it all into one thing: cost-ranked problems. Now your team knows exactly what to work on Monday morning.

Prove ROI to Finance (Finally)

Every kaizen project tracks dollars saved, not just "completion %". When your CFO asks "what did that improvement initiative deliver?", you show them: "$287K saved, here's the data." No more defending CI budgets.

Make Focused Improvement Actually Focused

TPM's Focused Improvement pillar works—when you focus on the right things. Kaizely ensures every project targets verified cost drivers. Attack your 16 major losses in priority order, not randomly.

Turn Every Problem Into Measurable ROI

-

Instant Cost Visibility, Zero Manual Work

Automatic integrations eliminate spreadsheets and instantly convert every loss into dollars. See your real-time cost impact across all 16 major loss categories—no data entry, no calculations, just financial clarity.

-

Fix the Problems That Actually Pay Back

Launch projects ranked by financial impact, not gut feeling. Every dollar spent on improvement targets your biggest cost drains. Track ROI in real-time and prove the value of every kaizen completed.

-

Deploy Expertise Where It Delivers Maximum ROI

Match skilled team members to high-cost problems automatically. Ensure your best people solve your most expensive issues first—maximizing the dollar impact of every improvement hour invested.

-

Proven Methods + Automatic Cost Tracking = Measurable Results

TPM and Kaizen frameworks have always worked—but never with built-in dollar tracking. Now every 5 Why, every countermeasure, every improvement is measured in dollars saved, not just process completion.

MyTasks: Run Your Kaizen Like a Kanban

Turn improvement projects into clear, trackable work—and track the cost impact of every task completed.

A simple, repeatable task workflow

- Backlog Capture tasks, assign context, and prioritize what matters most.

- Ready Clarify owners and definitions of done before work starts.

- In Progress Keep work moving and make blockers visible to the team.

- Review / Verify Confirm the fix works and the loss impact is validated.

- Done / Sustain Lock in standard work and ensure the improvement sticks.

From Data Chaos to Focused Action

Skip the spreadsheets and go straight to solving your biggest problems

Connect & Automate

Integrate with your existing systems. Kaizely automatically collects, organizes, and stratifies loss data by cost impact—no manual work required.

Launch Smart Projects

Issue continuous improvement projects targeting your worst costs. Use TPM/Kaizen tools with team members who have the right skills for the job.

Measure & Improve

Track real-time cost reductions and ROI. Develop your team through cross-training while sustaining improvements that last.

Simple, Transparent Pricing

Per-facility pricing with unlimited assets and users—scale your operations without limits

*All plans subject to 5% annual increase

Starter

per facility

- Single manufacturing site

- Unlimited assets/machines

- Unlimited users

- Standard integrations

Integration Options

Standard Setup (Included)

CSV import, public API access, and self-service integration tools. Most customers complete setup in 1-2 weeks using our documentation and standard connectors.

Custom Integration Development (Optional)

Need us to build a custom connector for your legacy OT systems? We'll develop, test, and deploy a production-ready integration specific to your environment.

- Custom OT/MES/SCADA connector development

- Data mapping and validation

- White-glove onboarding and training

- 30 days post-launch support

- One-time fee: $10,000 (first facility)

- Additional facilities: $7,500 each

Ready to Transform Your Operations?

Be among the first to transform your operations with Kaizely